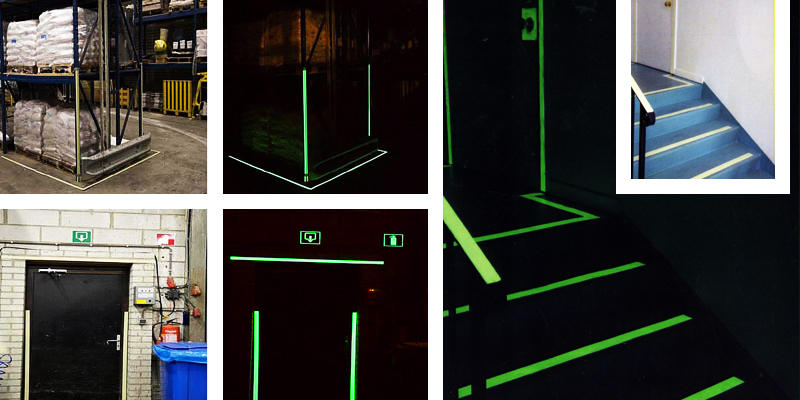

Nightstar is a photo luminescent coating that absorbs either natural or artificial light and converts it into an intense glow for 10 + hours after the original light source is removed. It is resistant to UV attack. Nightstar will clearly signify objects, markings and signs in complete darkness. Nightstar is odourless, 100% solvent free and chip resistant. It can be rolled or brushed on. It is a single component and requires no mixing with hardeners, catalysts or other liquids.

Uses

- Stair treads, risers, handrails.

- Civil engineering and mining.

- Aviation, Runways and Heliports.

- Railways, Platforms, Subway stations & Carriages.

- Roadways, bike paths & residential markings.

Shipping and marine traffic markers. - Resorts where lighting is limited to identify streets, walking trails, beach access, building identification.

- Manufacturing and Medical Facilities.

- Directional Signage on walls and floors.

Benefits

- Glows intensely for 10+ hours after light source is removed.

- Forms durable, UV resistant traffic bearing surface.

- Fast curing, 100% solids, 1-component product.

- Odourless.

- Contains solvents.

- Can be used in extreme hot and cold environments.

- Applies to concrete, metal including stainless steel, glass, GRP, wood, tile and much more.

- Environmentally friendly.

Technical Data Sheet

Description

Nightstar is a photo luminescent (glow in the dark) Coating. This is a highly abrasion and UV resistant, single component product which contains no sovents and is odourless.

Basis

Shelf life and storage conditions

Application Temperature

Thickness (smooth surface)

Density

Drying time (touch dry)

Foot trafficable

Full Cure

Coverage

(Roughness, unevenness, highly porous surfaces must be taken into account)

Packaging/ Article

Tub 1litre

Uses

Nightstar is suitable for the following applications:

-

- As clear demarcation of escape routes or emergency exits.

- Demarcation of stair treads landings, exits and entrances, danger zones, congregation and smoking areas.

- Hazard warnings in thoroughfares, work places and public transport.

- Marine craft, shipping and other on and offshore marine applications.

- Roads and runways and railways.

- Locations which are difficult to illuminate (e.g. unlit areas with limited power supply).

Surfaces

Should always be applied to a sound, white or light colored surface for optimal results:

- Uncoated metal

- Concrete

- Gypsum

- Glass

- Ceramic Tiles

- Treated or untreated wood

- Masonry

Where a quality base coat is needed, particularly in the case of flooring or metal protection, Smarttech Polarcoat is recommended.

Advantages

Nightstar assists in the reduction of energy costs, where artificial lighting can be significantly reduced along with other advantages such as:

- Instant, intensive glow after removal of light source. The surface will continue to glow for at least 10 hours after light source is extinguished.

- Very rapid recharge when exposed to natural or artificial light.

- Single component liquid which is directly applied from the container.

- No mixing of components.

- Cures quickly, to a durable surface with consequent reduced down time.

- Is applied in a single coat over a white or light colored surface e.g. Smarttech Polarcoat

- Superb adhesion to wood, metal, gypsum plaster, most coated surfaces, concrete & masonry, glass & ceramics and many other surfaces.

- Odourless, no vapors or dangerous solvents

- Seamless and joint free, monolithic surface

- Offers good UV resistance

- Fast curing from 0°C

- Isocyanate free

Directions for Use

Surface Preparation

Surfaces must be sound, clean, free of dust and loosely adhering particles, all traces of corrosion, oil, fats, mildew and algae. Concrete and masonry surfaces, ideally, should not have a moisture content above 8%. Surfaces should be free of laitance and efflorescence as well as any other deposits that may interfere with the bond to the concrete or masonry.

Before applying Nightstar surfaces must be wiped down with a cleaning fluid such as denatured alcohol or other appropriate cleaning method ensuring that no residue remains.

The product must be gently stirred before use, taking care not to entrain air, as this will create air bubbles in the coating which may form small craters on curing. Should this occur allow the product to stand with the lid in place for between 5 and 10 minutes to allow air to escape.

After preparation Smarttech Polarcoat should be applied as basecoat, where surfaces are not already white, or a very light pastel shade. Polarcoat is applied at approx. 0.25l/m2(approx. 0.25mm thick) by brush or roller. Allow to cure until a subsequent coat will not disturb the surface (between 1 and 2 hours depending upon temperature and humidity).

Curing

The surface of Nightstar becomes touch dry after 2 hours and is foot trafficable after 8 hours depending upon temperature and humidity.

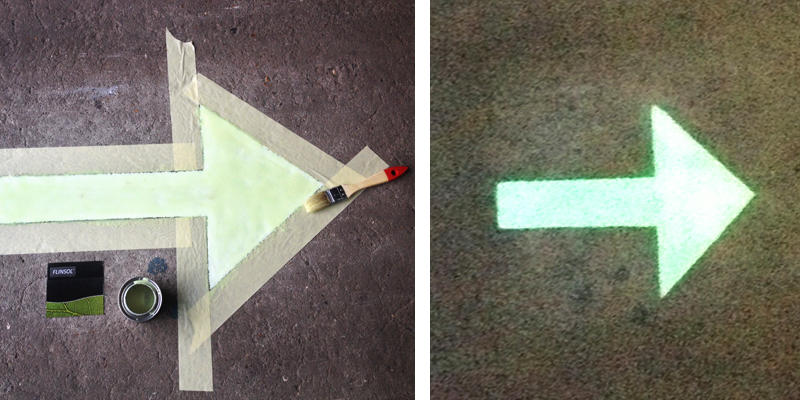

Application

Apply a coat of Nightstar at a mini-mum rate of 0.375l/m² (0.375mm thick). Allow to dry and apply a second coat at 0.375l/m² to achieve a final thickness of 0.75mm for optimum product perfor-mance.

Color

Light Yellowish Green

Cleaning

Uncured Nightstar can be removed with White Spirits. Cured Nightstar can only be removed mechanically.

Application Conditions

Ambient Temperature -5°C to + 45°C

Surface Temperature -5°C to + 55°C

Note: Do not apply over frozen matter!

Coverage

Nightstar

Smooth Surfaces- min. 0.75l/m2 (0.65 to 0.75mm thick)

Drying time

Approx. 2 hours at 15°C and 50% rel. Humidity

Fully trafficable approx. 8 hours after at 15°C and 50% rel. humidity.

Fully cured after 14 days

Shelf Life

Unopened Containers:

12 months from production.

Caution

Carefully read the Safety Data Sheet for Polarcoat before use. Avoid con-tact with eyes and skin as this may cause irritation. Should contact with eyes occur, rinse for 15 minutes under running water. If swallowed do not induce vomiting and seek the advice of a physician.

affected by substrate, environment, type of building element being coated etc.

Note

The information contained in this technical data sheet is based upon our experience and is therefore not binding. All data are laboratory values, which may differ in practice. Therefore, these represent no assurance of characteristics. This data is given in order to allow compliance with respective local specificities. The variety of possibilities and the specific project details in combination with the products cannot be handled within the framework of this data sheet. If you have questions, please contact us.

It is the user’s responsibility to be informed about the characteristics of the products as well as the technical information and proper processing. Please take careful note of all manufacturers’ specifications, e.g. information on surface pretreatment. A specific result cannot be guaranteed due to differing prevailing individual conditions, which can lead to differing result. Preliminary tests are advised to test for the desired result.