Surefloor is the latest alternative to epoxy and polyurethane resins that can be used to refurbish the floors in any industrial, commercial, medical or manufacturing facility. This single component high performance coating surpasses the quality of traditional epoxy resins and polyurethanes that have been widely used in the past. Surefloor is a 100% solids coating that is solvent free and odourless. It is a single component and requires no mixing. It comes in a variety of colors and finishes ranging from a smooth, high gloss to a non-skid surface. It cures to a UV resistant, walkable surface in a few hours and has remarkable adhesive and protective properties. Surefloor repairs fissures and cracks as well as strengthening and restoring failing floors. For Antislip Test Data refer to Surefloor Technical Data Sheet.

Uses

- Cold Rooms and Cold Storage and other Warehouses.

- Food Handling and Food Processing Rooms e.g. Abattoirs, Bakeries, Supermarket Prep. Areas, Restaurants and Commercial Kitchens.

- Clean Rooms in electronic manufacturing and medical facilities.

- Manufacturing Facilities, Showrooms, Workshops, Garages and many more.

- Driveways, Walkways and Balconies

Benefits

- Odourless. 100%Solvent Free.

- Contains no solvents. Non Toxic.

- Single component. No Mixing.

- Applies easily using brush, roller or spray.

- Will cure in temperatures well below freezing.

- Opened containers can be resealed for later use avoiding significant waste.

- Applies to glass, ceramic tiles, concrete, metal including stainless steel, GRP, wood and many other surfaces.

- Withstands mandatory cleaning using aggressive cleansers with high pressure water jets at 70ºC.

- Has good vapor transmission capability allowing trapped moisture to escape.

- Resistant to UV attack

- Resistant to acids, alkalis, petroleum solvents, hydraulic fluid and other aggressive chemicals.

- Environmentally friendly.

Technical Data Sheet

Description

Surefloor is a single component, 100% solids, solvent free floor coating system. It can be applied to give a highly effective anti-slip finish as well as very smooth high gloss finishes where required. Surefloor in either form delivers an extremely durable abrasion, impact and chemical resistant surface. Surefloor is UV stable making it suitable for exterior applications. The properties of Surefloor create optimal conditions to resist the growth and accumulation of bacteria on the easy to clean surface of the coating. Also, the ability to apply the product at low temperatures with little effect on curing time is setting new industry standards.

At junctions Surefloor used in conjunction with Smarttech Fabric creates a monolithic surface, leaving no crevices for the collection of contamination or bacteria.

Type

Shelf life and storage conditions

unopened 12 Months, Storage Temp. +5 to 32°C

Application Temperature

-10°C – 45°C (Ambient)

-10°C – 50°C (Surface)

Application possible at -23ºC with special conditions. Contact technical department.

Thickness (smooth surface)

Total weight

Drying time (touch dry)

1 hours at 0°C and 50% rel. humidity

Water vapour Permeability ASTM E-96

24×10-8 g.s-1.m-2.Pa-1 ( 4.2 perms) @ 0.5mm thick

Trafficable

Lightly walkable at 2 hours at 0°C and 50%RH

Full Cure

Taber Abrasion ASTM D-4060-14

Wear Index I=58 @1000cycles

Coverage

Check specific application in “Coverage” text below

Caution: Surface unevenness & absorbency will consume more product to achieve desired thickness

Anti Skid BS7976-2 Pendulum Test (Using Smarttech Standard Quartzsand)

PTV Dry 72 and PTV Wet 63

(“Low Risk” floor values are greater than 36)

Container Size / Article - Packaging

Surefloor Colours – 3.5 litre pail (Special Colours upon request)

Surefloor Clear – 3.5 litre pail

Smarttech Fabric – 100mm x 90m roll

Smarttech Coloured Quartz Sand – 25kg bags

Smart Block Matt Sealer – 3kg Kit

Uses

Surefloor is successfully used on the floors of:

- Cold Rooms & Cold Storage warehouses

- In food handling and food processing rooms, e.g. Abattoirs, Bakeries, Supermarket Prep. Areas, Restaurants and Commercial Kitchens

- Clean rooms in electronic manufacturing, medical facilities and

laboratories.

- Showrooms

- Workshops and Garages.

Substrates

- Concrete & Masonry

- Glass, Ceramic & Ceramic tiles

- GRP Panels(Glass Reinforced Polyester)

- Wood *

- Metal (including Stainless Steel)

Advantages

Surefloor offers the following advantages:

- 1-component, no mixing

- Ready to use

- Solvent free

- Containers can be resealed for future use

- Can be applied to damp surfaces

- Seamless, monolithic surface

- No joints

- No fissures or crevices for bacteria or germs to lodge

- Odourless – allowing application in close proximity to food products

- Fast curing from below freezing

- After curing it is resistant to most acids and alkalis, most petroleum solvents animal fats, blood and aggressive cleaning chemicals with 70ºC plus hot water pressure rinsing.

- Contains no isocyanates, reducing health concerns

- Adheres to most building surfaces without priming

Application

Surface Preparation

Surfaces must be sound, clean, free of dust and loosely adhering particles, all traces of corrosion, oil, fats. Mildew and algae must be removed with bleach solution.

Concrete and masonry surfaces should ideally not have a moisture content above 8%. Surfaces should be free of laitance and efflorescence as well as any other deposits that may interfere with the bond to the concrete or masonry.

Before applying Polarcoat, surfaces must be lightly abraded and wiped down with a cleaning fluid such as denatured alcohol or other appropriate cleaning method ensuring that no oils, fats or other residue remain. Surefloor must be gently stirred before use, taking care not to entrain air as this will create air bubbles in the coating which may form small craters on curing. Should this occur allow the product to stand with the lid in place for between 5 and 10 minutes to allow air to escape.

Curing

Touch dry after 1 hours at 0°C and 50% RH

Trafficable after 2 hours at 0°C and 50% RH

Fully cured after 14days.

Cleaning

Uncured Surefloor can be removed with Denatured Alcohol. Cured Surefloor can only be removed mechanically.

Application Instructions

At all junctions between panels, dissimilar substrates, pipe or conduit penetrations and at plane junctions, apply Smarttech Fabric to reinforce these locations.

Apply a moderate coat of Surefloor by brush or roller symmetrically over the joints covering approximately 50mm each side of the junctions (e.g. panel joints, floor to wall sealing ). Lay in the 100mm wide fabric symmetrically over the joint and imbed using a brush or roller. Make sure that no bubbles or creases appear in the fabric. At the same time apply a moderate coat of Surefloor over the entire area to be treated. Allow to become touch dry (about 1 hour at 0ºC and quicker at higher temperatures and relative humidity).

Coverage

The coverage of Surefloor will vary depending upon thickness and finish chosen for the application as well as porosity of substrate. Some guidelines are:

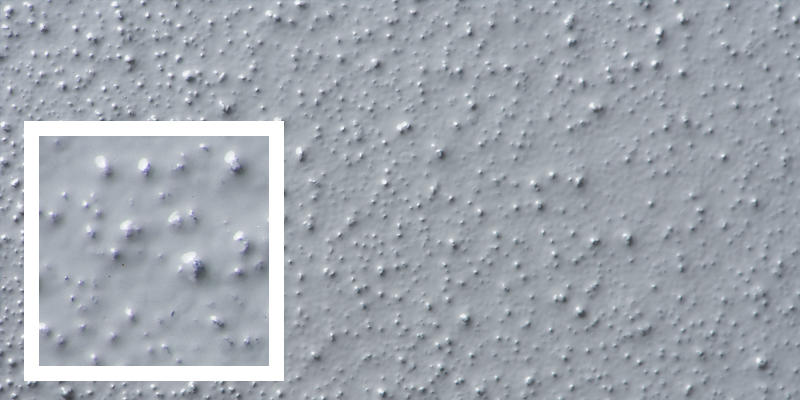

Smooth Solid Colour

Smooth substrates 0.5 l/m2

This includes total coverage for both coats.

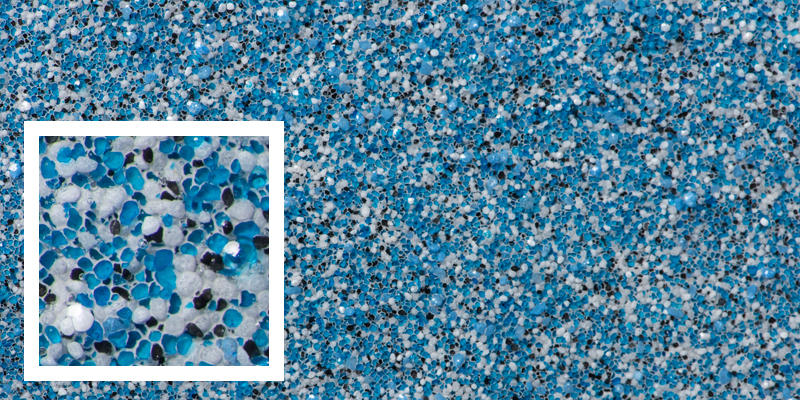

Anti-slip Solid Colour

Smooth substrates 0.55 l/m2

This includes total coverage for both coats.

Anti-slip Quartz Finish

Smooth substrates.

Surefloor (colour) 0.25l/m2

Surefloor (clear) 0.3 l/m2

Smooth Quartz Finish

Surefloor (colour) 0.25 l/m2

Surefloor (clear) 0.6 l/m2

Total for two coats of Clear

Colours & Finishes

White, Grey, RAL Yellow, Red, Blue and Green Safety colours and Clear as well as natural coloured quartz sand finishes.

Solid colours as well as Coloured quartz finish are available in anti-slip or high gloss depending on desired surface use. Additional colours available upon request.

Note: Slight variations in colour can occur between batches.

Priming

Metal, Concrete and Masonry, Glass or Ceramic generally require no priming.

On wooden surfaces, only where tannin bleed may be expected, or on concrete or other surfaces where contamination might cause staining, prime surface with Smart Block Primer. This will prevent the new application from becoming stained. For other substrates not mentioned above contact our customer service.

Application Conditions

Ambient Temperature: -10°C to 45°C

Surface Temperature: -10°C to 50°C

Do not apply over frozen matter!

Storage

Unopened containers:

12 months from manufacture date.

Opened Containers:

To lengthen storage time, fill headspace above Surefloor with nitrogen gas and immediately replace lid securely. Shake closed container gently before storing.

Resistance to Chemicals

Chemical resistance tests show that cured Surefloor is resistant to many solvents, acids and alkalis like

- Diesel

- Acetone

- Butanol

- White spirits

- Sulphuric Acid 5%

- Hydrochloric Acid 5%

- Sodium hydroxide 5%

- Animal Fats and Blood

- Commercial cleaning chemicals

It is advisable to allow 48 hours cure before subjecting surfaces to aggressive cleaning chemicals.

Caution

Carefully read the Safety Data Sheet for Surefloor before use. Avoid contact with eyes and skin as this may cause irritation.

Note

The information contained in this technical data sheet is based upon our experience and is therefore not binding. All data are laboratory values, which may differ in practice. Therefore, these represent no assurance of characteristics. This data is given in order to allow compliance with respective local specificities. The variety of possibilities and the specific project details in combination with the products cannot be handled within the framework of this data sheet. If you have questions, please contact us. It is the user’s responsibility to be informed about the characteristics of the products as well as the technical information and proper processing. Please take careful note of all manufacturers’ specifications, e.g. information on surface pretreatment.. A specific result cannot be guaranteed due to differing prevailing individual conditions, which can lead to differing result. Preliminary tests are advised to test for the desired result.